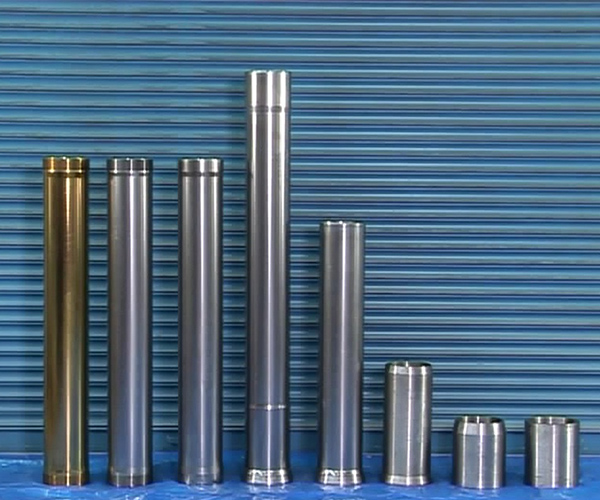

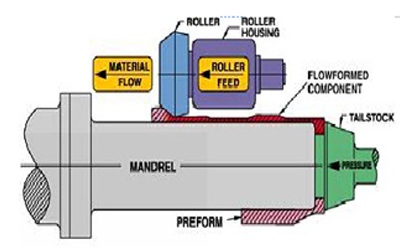

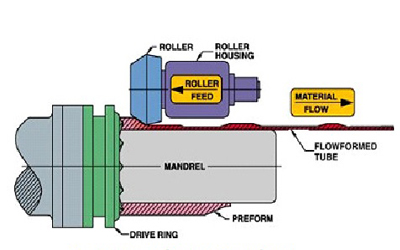

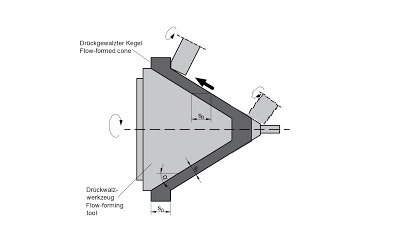

Flow forming is simply a cold forming process by which a thick-walled cylindrical cup called a preform is stretched over a rotating mandrel by three forming rollers, which are arranged equidistant, and at 120 degrees to each other. Six world-class flow-forming machines to maintain the delivery requirements of customers.

Flow forming can be done on different material as below mentioned :

Capacity: